Thermal imaging Perth

Thermal imaging is a wonderful, non-destructive technique that is used by electricians throughout the world. When used right, it allows the detection of problems that perhaps aren’t visible to the naked eye, or which are hidden behind walls, inside machinery or in other hard to access places.

Here at Holdens Electrical Contracting we use thermal imaging techniques to complement the skills of our various electrical contractors. This allows them to identify weak spots in your electrics, to prioritise repairs and to evaluate the overall health of your business’s electrical systems.

Here at Holdens Electrical Contracting we use thermal imaging techniques to complement the skills of our various electrical contractors. This allows them to identify weak spots in your electrics, to prioritise repairs and to evaluate the overall health of your business’s electrical systems.

Call us today

(08) 9459 1538

How Does Thermal Imaging Work?

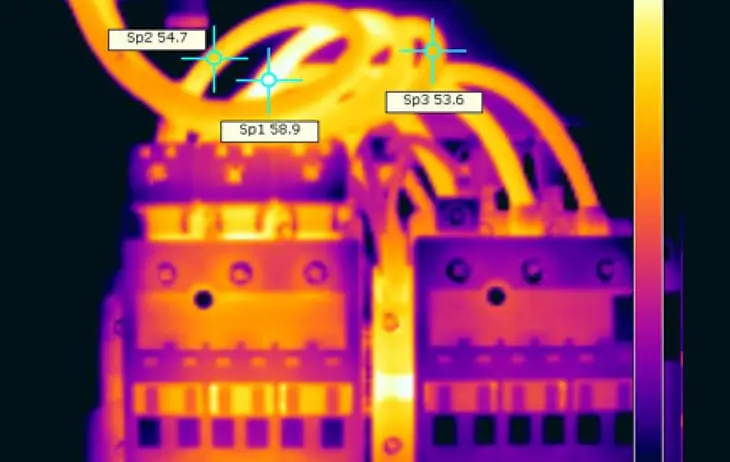

Basically, thermal imaging uses various infrared imagers to map out heat patterns in an area. Since most electrical equipment and infrastructure radiates heat of some form, thermal imaging can be used to map the location and condition of wiring, cables and other electrics – even if they are hidden within walls or other structures.

When used correctly by a trained professional, thermal imaging will help your electrician identify problems or potential problems with your electrics. Usually, areas which are damaged or which are wearing out will radiate more heat than ‘healthy’ electrics, which means that they will shine brighter on a thermal image

When used correctly by a trained professional, thermal imaging will help your electrician identify problems or potential problems with your electrics. Usually, areas which are damaged or which are wearing out will radiate more heat than ‘healthy’ electrics, which means that they will shine brighter on a thermal image

Why Should I Use Thermal Imaging?

To put it simply, thermal imaging allows your electrician to conduct a full inspection of your electrics without damaging any other infrastructure. It allows them to identify problems in electrical components which may appear healthy to the visible eye, which means that they can be fixed before they cause major problems.

One of the major uses of thermal imaging technology is in an industrial setting. Most industrial settings are tough on electrics, which means that regular inspections are essential. Thermal imaging allows you to pick up problems while they are still small, which in turn means that they can be fixed without causing major downtime. As any business owner knows, ‘time is money’, and downtime can be very costly.

One of the major uses of thermal imaging technology is in an industrial setting. Most industrial settings are tough on electrics, which means that regular inspections are essential. Thermal imaging allows you to pick up problems while they are still small, which in turn means that they can be fixed without causing major downtime. As any business owner knows, ‘time is money’, and downtime can be very costly.

Using Thermal Imaging Allows Us To Assign ‘Repair Priority Ratings’

Any member of the Holdens Electrical Contracting team who is sent to conduct thermal imaging on your premises will be fully trained and experienced. This means that they will be able to provide a clear, informational evaluation about the health of your electrical systems. One of the major components of such an evaluation is repair priority ratings.

A repair priority rating is assigned to any electrical components which appear to be worn, damaged or otherwise flawed. They are designed to reflect the severity of the problem, with a higher repair priority rating reflecting more critical problems. These ratings are subjective, but we recommend using them to inform maintenance decisions to reduce the risk of large problems that can lead to significant downtime.

A repair priority rating is assigned to any electrical components which appear to be worn, damaged or otherwise flawed. They are designed to reflect the severity of the problem, with a higher repair priority rating reflecting more critical problems. These ratings are subjective, but we recommend using them to inform maintenance decisions to reduce the risk of large problems that can lead to significant downtime.

Get In Touch Today!

If you’re interested in finding out more about how our thermal imaging services can benefit you, get in touch with our friendly customer service team today. We can answer questions, arrange a site inspection or simply run you through the basics of thermal imaging and why you should be using it. Drop past our office, give us a call or even send us an email today!